Parachute Performance

PARACHUTE CHARACTERISTICS AND PERFORMANCE

Parachutes are the building blocks of any parachute recovery system. Their performance characteristics must be known and considered in selecting and designing a system. In the early 1920s, the circular, flat parachute manufactured from solid cloth was the primary parachute used for the rescue of aviators, for sport jumping, and for airdrop of light loads. In the 1930s, the military began using parachutes for the airdrop of troops and cargo and for the landing deceleration of aircraft. Beginning in the 1940s, parachutes were used for recovery of unmanned aircraft, missiles, ordnance devices, and, later, recovery of manned and unmanned spacecraft.

These new parachute applications resulted in, or were the result of, the development of numerous new types of parachutes. The new parachutes were superior to the circular, flat, solid textile parachutes in stability, opening forces, and drag. Some of the new types could be used for supersonic applications and others for descent in a gliding mode. However, the superior performance characteristics were not combined in one parachute. Prudent analysis, therefore, is a requisite for matching the appropriate parachute to the desired application.

5.1 PARACHUTE DECELERATOR TYPES

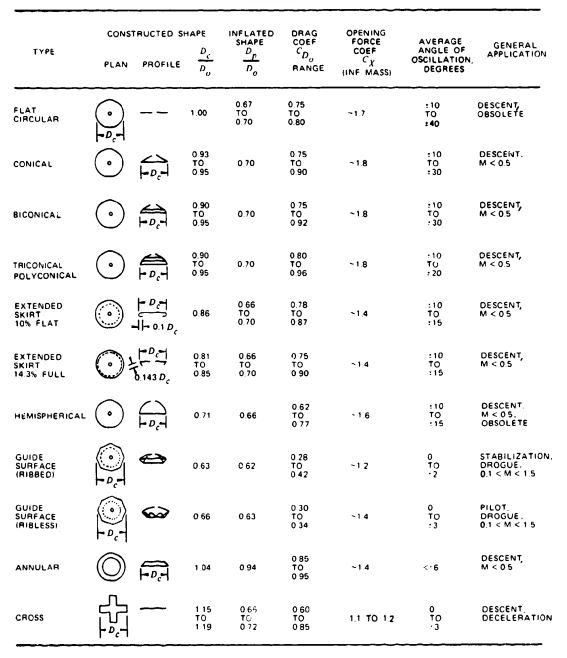

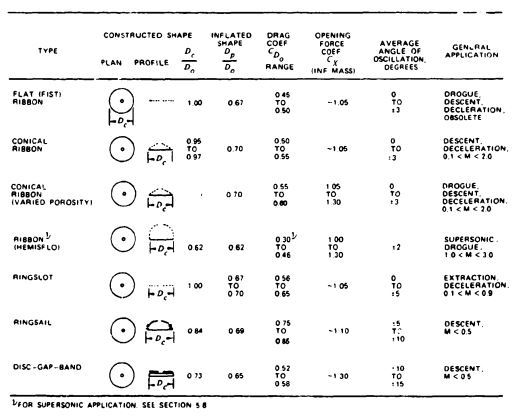

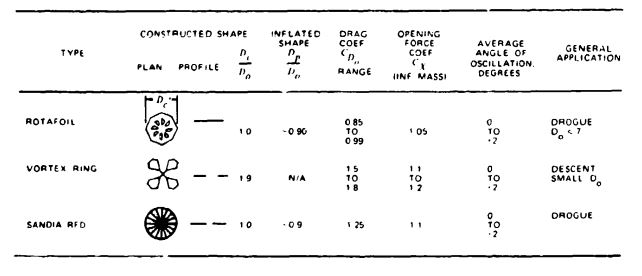

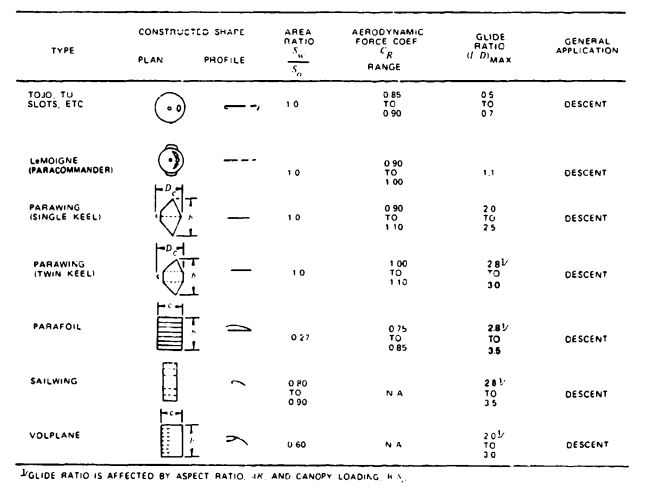

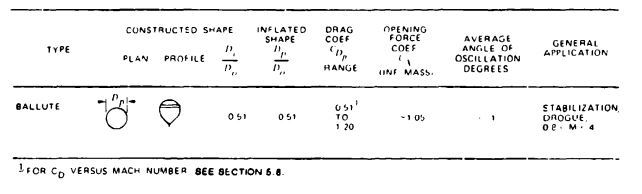

Common parachute types, varying in stability, drag, opening behavior, velocity capability, and other design and performance characteristics, are listed in Tables 5-1 through 5-5, which are updated from the tables in Reference 2.1. The performance data are to be used for preliminary considerations only. Detailed performance data are found in sections 5.2 through 5.10 and in the references (section 5.12). The following comments refer to the column headings in Tables 5-1 through 5-5.

Constructed Shape. The Plan and Profile columns define the constructed diameter and the cross section of the parachute canopy.

, the constructed diameter of the canopy, can be obtained from the drawing of the specific parachute.

Nominal Diameter. Do, the nominal diameter of the parachute, can be calculated from the total canopy surface area, So, including the area of the vent and all other openings:

Inflated Shape. , the projected diameter of the inflated parachute canopy, is best calculated from the projected or inflated canopy area, , as measured in wind-tunnel tests. The projected diameter of a parachute varies with parachute type, canopy porosity, suspension-line length, velocity, and canopy design. A large projected diameter, , will generally result in a large drag coefficient, Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle C_{D_o}} . The ratio of projected diameter to nominal diameter, Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle D_p/D_o} , is an indication of the drag effectiveness of the parachute design, the larger the projected diameter in relation to the nominal diameter, the larger the drag coefficient.

Drag Coefficient. is the drag coefficient related to the total canopy surface area, . The drag coefficient indicates how effectively a parachute canopy produces drag with a minimum of cloth area, thereby minimizing weight and volume.

Opening-Force Coefficient. , the opening-force coefficient, indicates the difference between the instantaneous opening force and the steady drag force at constant speed. This condition, called the infinite mass case, is obtained in wind-tunnel tests and in parachute applications with high canopy loadings, , as exemplified by aircraft deceleration parachutes and first-stage drogue chutes.

Average Angle of Oscillation. The angle of oscillation is measured in wind-tunnel tests or during free-flight tests. Oscillation on most solid textile parachutes varies with size and descent velocity. Large parachutes oscillate less than small parachutes. Unstable parachutes tend to descend in an oscillating mode at rates of descent in excess of 25 ft/s, glide at descent rates below 15 ft/s, and mix glide and oscillation during medium rates of descent.

General Application. The general application column in Tables 5-1 through 5-5 indicates the primary use of the particular parachute type.

, in Table 5-4 is the wetted upper canopy surface area on gliding parachutes.

in Table 5-4 is the ratio of the upper surface area to total cloth area, including all ribs and stabilizer panels.

Referenced reports for most of the listed parachutes will be found in subsequent sections of Chapter 5, but primarily in section 5.2, Parachute Drag and Wake Effects.

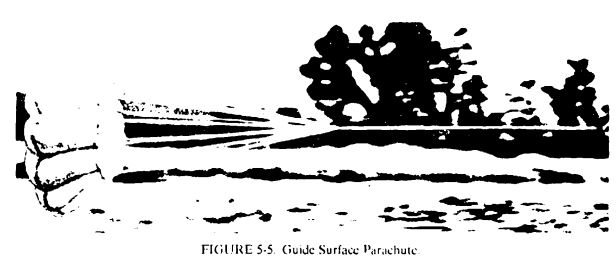

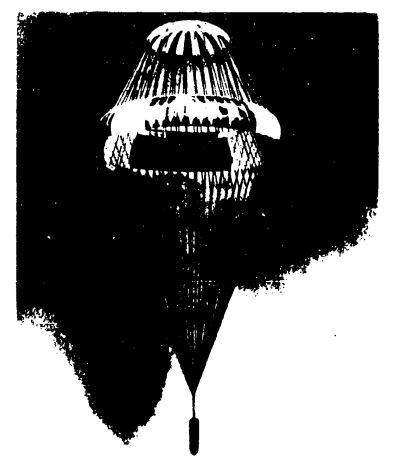

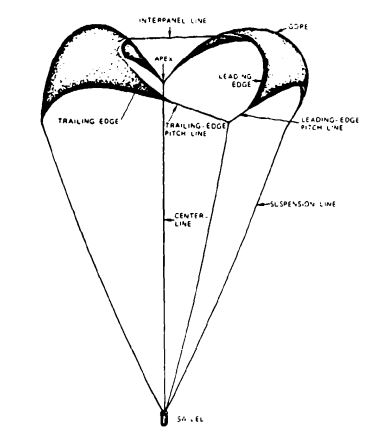

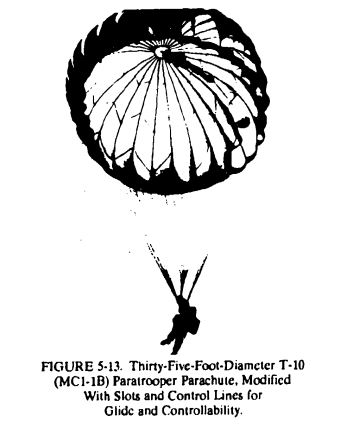

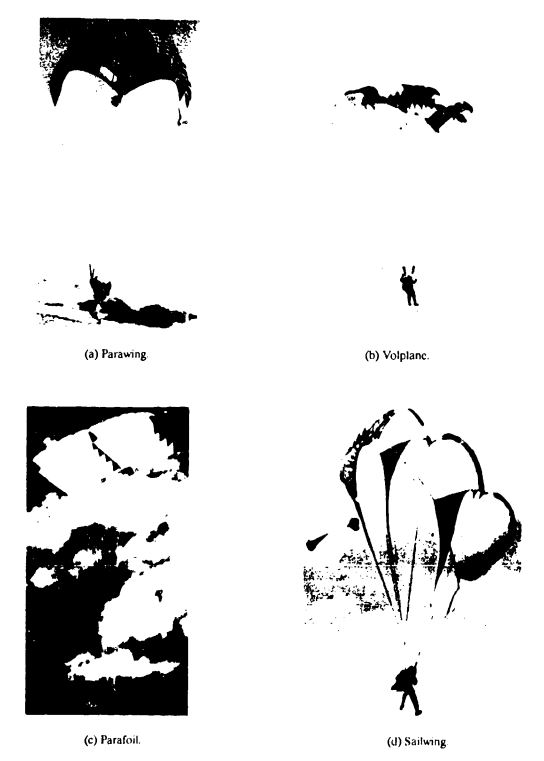

Figures 5-1 through 5-15 show some of the more common parachute-type decelerators listed in Tables 5-1 through 5-5.

Note: Maneuverable parachutes with a glide ratio L/D of 2.5 or better have been defined in the literature as "hi-glide parachutes." This includes the parawing, the parafoil, the sailwing, and the volplane.

5.2 PARACHUTE DRAG AND WAKE EFFECTS

Parachute drag is an important performance parameter. because it determines the rate of descent, generally a primary performance consideration in the design of a parachute system. To maintain a required constant rate of descent, the drag of the parachute must equal the weight of the total system, as discussed in Chapter 4. The parachute drag, D, is

where

is the parachute drag coefficient related to the canopy surface area, dimensionless

is the canopy surface area, including the vent area and all openings and slots in the canopy,

is the dynamic pressure, equal to

For a given rate of descent, the dynamic pressure, q, is a fixed value. The product, , * is called the drag area of the parachute and is measured in square feet. A large drag coefficient, ,will result in a small canopy surface area, , and a low parachute weight and volume. Because these characteristics are highly desirable for large-diameter, final descent parachutes, a large drag coefficient is frequently the deciding factor in the selection of a parachute. The following design features and parachute canopy characteristics are known to produce high drag coefficients:

1. Conical, multi conical, or quarter-spherical canopy shapes

2. Rectangular or triangular canopy shapes

3. Long suspension lines

4. Low canopy porosity

5. Annular canopy shapes

6. Rotating parachutes

7. Gliding parachutes

The drag coefficient, , refers to the vertical component of the parachute velocity, as discussed in Chapter 4.

The glide velocity of a gliding parachute changes little with glide angle. However, the vertical component of the glide velocity (the rate of descent) decreases notably with an increasing glide ratio.

Rectangular and triangular parachutes up to personnel-parachute size have been used successfully at lower speeds. Deployment of large rectangular and triangular parachutes has caused problems. The noncircular canopy design makes it difficult to maintain tension on all canopy elements during deployment and inflation.

Long suspension lines increase the inflated diameter of the canopy and result in a larger drag coefficient, which, for a given rate of descent, produces a smaller diameter and a lighter parachute assembly.

Rotating parachutes have been used successfully with diameters up to 10 feet. Attempts to use larger rotating parachutes have resulted in poor deployment and canopy wrap-up before full inflation. Inaccuracies in the angle of pitch of individual gores cause variations in parachute rotation and drag coefficient.

Decreasing the porosity increases the drag coefficient but also produces a less stable parachute and a higher opening force.

Canopy profiles of quarter-spherical shapes and the similar tri conical shapes have shown the highest drag coefficients for circular canopy designs. * In this manual, , and are interchangeable.

5.2.1 Canopy Shape and Suspension Line Length Effects

In 1949, the U.S. Air Force conducted model drop tests of 1600-square-inch parachutes under controlled conditions in the Lakehurst, New Jersey, airship hangar (Reference 5.1). These tests established several facts previously unknown or only suspected.

Solid textile parachutes of a round or cornered design and with a flat or shaped profile descended in a vertical line, but oscillated violently when dropped at rates of descent greater than 30 ft/s. The same parachutes, when dropped with a low weight, had a 10-ft/s rate of descent and descended in a stable, non oscillating attitude, but glided at angles up to 45 degrees. In the 15-to 25-ft/s descent range, these parachutes combined oscillation with straight descent, or with glide but no oscillation. Gliding resulted in a low vertical velocity component and a high drag coefficient. Vertical descent with oscillation at the higher rates of descent resulted in lower vertical drag coefficients.

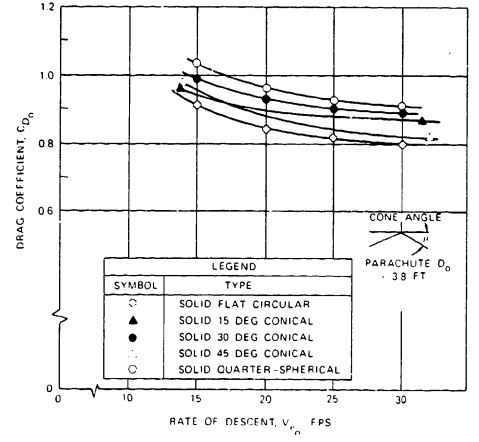

For the same surface areas, conical and quarter-spherical canopies had higher drag coefficients than circular flat canopies. Figure 5-16 shows that, at a rate of descent of 20 ft/s, a 30-degree conical parachute has a 9.5% higher drag coefficient than a flat, circular canopy, and a quarter-spherical canopy has a 14.5% higher drag coefficient. These tests were the basis for the quarter-spherical profiles of the ringsail and the triconical parachute canopies.

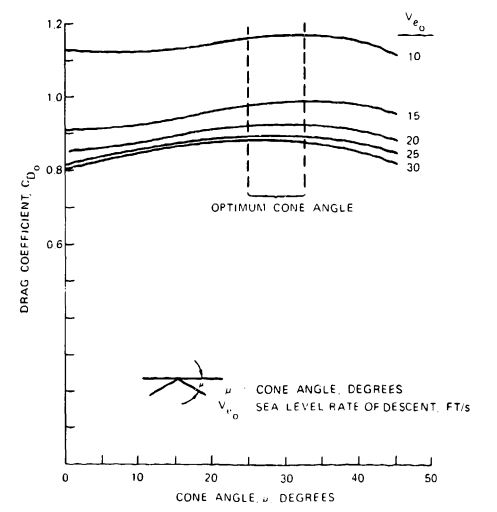

The model test results were confirmed in full-scale drop tests conducted at El Centro, Calif., with modified 28-foot-diameter personnel parachutes. Successive gores were removed from a 28-foot-diameter, flat, circular canopy to convert it into a conical parachute of increasing cone angles. The vertical drag coefficient, , increased with increasing cone angle and decreasing rates of descent. A cone angle of 25 to 30 degrees was the optimum angle, as shown in Figure 5-17 and Reference 5.2.

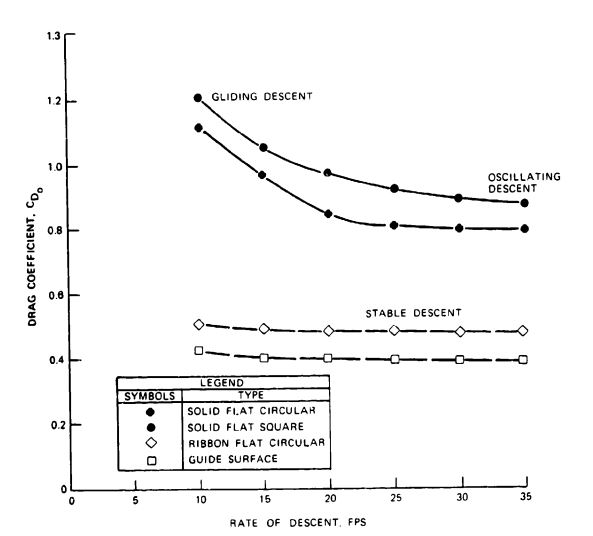

Data from Reference 5.1 (Figure 5-18) demonstrate the difference in drag coefficient, , versus rate of descent for four parachute types. Two types are stable: a flat, circular, ribbon parachute and a guide surface parachute. Two types are unstable: a solid textile, circular, flat parachute and a solid textile, square, flat parachute. Figure 5-18 clearly shows the characteristic that unstable parachutes increase their drag coefficient with decreasing rates of descent because of the change in descent behavior from oscillation to glide.

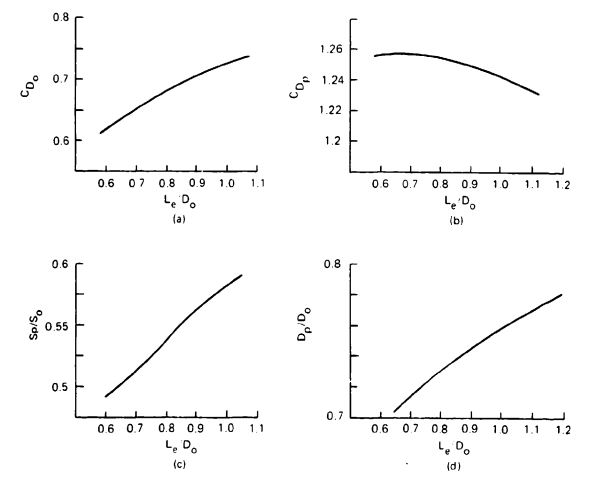

An increase in drag coefficient for a specific parachute can be accomplished by increasing the length of the suspension lines (see Figure 5-19). The increase in suspension-line length causes the parachute to open wider with a larger inflated area, , and inflated diameter, . The drag coefficient, related to the inflated (projected) area, , decreases slightly with an increase in line length and a related increase in projected diameter (see Figure 5-19b). However, the drag coefficient clearly increases with an increase in suspension-line ratio, (Figure 5-19a).

. The drag coefficient, , related to the inflated (projected) area, , decreases slightly with an increase in line length and a related increase in projected diameter (see Figure 5-19b). However, the drag coefficient clearly increases with an increase in suspension-line ratio, (Figure 5-19a).

The slopes of the curves for area and projected diameter growth in Figure 5-19 indicate that using suspension-line ratios larger than 1.1 may have provided additional drag.

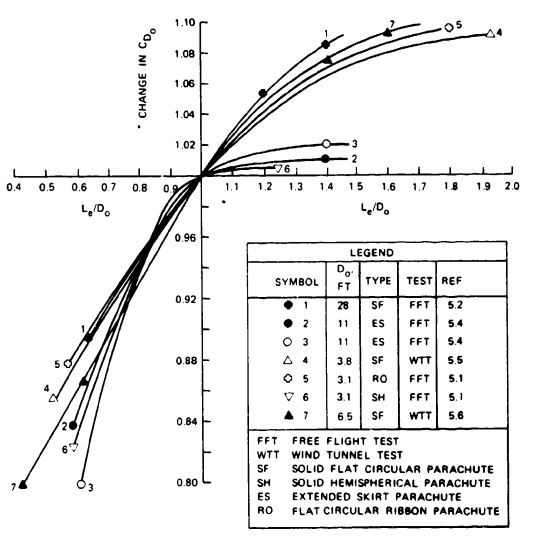

These data were obtained in model tests with 1-meter (3.3-foot)-diameter parachutes. Reference 5.3 provides background on the tests. Figure 5-20 shows the possible increase in drag coefficient for line ratios, , up to 2.0. Parachutes with no skirt restrictions, such as flat and conical circular parachutes, increase the drag coefficient up to line ratios of 2.0. Parachutes with skirt restrictions, such as extended skirts and hemispherical canopies, show little drag coefficient increase at line ratios above 1.1. The data in Figure 5-20, taken from United States, British, and German sources, show relatively good concordance.

Calculations indicate that line-length ratios above 1.5 may be detrimental because of the associated weight increase of the longer lines. Systems that employ parachutes in clusters or use first-stage drogue chutes require long risers. Parts of these risers may be replaced by longer suspension lines on the individual parachutes to increase parachute drag and decrease the required parachute diameter and parachute assembly weight.

5.2.2 Forebody Wake Effect

Parachutes are always used in connection with a forebody, such as a parachute jumper, an aircraft, a load platform, or an Apollo-type space capsule. Each forebody produces a wake

that affects the parachute, depending on the relationship of the inflated parachute diameter,

DP, to forebody diameter, DB, and the distance between the end of the forebody and the

leading edge of the inflated parachute canopy. Figure 5-21 illustrates the drag loss. A cargo

container descending on a 100-foot-diameter parachute produces little wake effect, because

both the diameter ratio, Dp/DB, and the distance between the container and the leading edge of

the parachute, LT, are large. The inflated diameter of the Apollo drogue chute was smaller

than the diameter of the Apollo spacecraft. The distance between the leading edge of the

parachute and the rear of the spacecraft was kept to a minimum to save weight. Many

parachute jumpers have experienced the failure of a spring-loaded pilot chute that was ejected,

but then collapsed and fell back on the jumper because of the blanketing or wake effect of the

jumper's body. 0 Tests conducted in the NASA and Wright Field vertical wind tunnels determined that for

vertical descending bodies, the parachute should be ejected to a distance equivalent to more

than four times-and preferably six times-the forebody diameter, into good airflow behind

the forebody. Applying the six-forebody-diameter rule has been successful on Apollo and

other programs. Ejecting the parachute from a horizontal attitude or sideways out of the

forebody wake can provide good inflation with shorter forebody-to-parachute canopy

distances. However, successful inflation with shorter distances should be proven in tests of the

most unfavorable-not the most favorable--deployment conditions.

Deploying a small parachute in the wake of a large forebody also causes considerable loss

in parachute drag and may affect the stability of the parachute. Drag losses of up to 25% have

been experienced in wind-tunnel and free-flight tests. Figure 5-21 presents parachute drag

losses caused by forebody wake measured in wind-tunnel and free-flight tests. The two dotted

lines (I in Figure 5-21) encompass parachute wake loss data measured in wind-tunnel tests by

the University of Minnesota and the California Institute of Technology (Cal Tech) (References

5.7 through 5.9). Superimposed on this wind-tunnel data are free-flight test results obtained on

the reefed 16.5-foot-diameter Apollo command module drogue chute tested behind three

different forebodies. This drogue chute was tested behind (1) an 11.9-foot, boilerplate

command module (CM) (II in Figure 5-21), (2) a 5.8-foot-diameter parachute test vehicle

(PTV) (III), and (3) a 36-inch-diameter instrumented cylindrical test vehicle (ICTV) (IV)

0 5-21

NWC TP 6575

Op 1.0 "3""

0.9

LEGEND

0.B FOREBODY CANOPY

0.7

I-. 01 1.0 D8__ __ _ __ __ _ __ __ _

Z B0 I DATA FROM REFERENCES 5.3 TO 5.11

M 0.6 13 APOLLO DROGUE CHUTE BEHIND CM" =

w In APOLLO DROGUE CHUTE BEHIND PTV"' =

0 I APOLLO DROGUE CHUTE BEHIND ICTVIJ =

I XS-2 DROGUE CHUTE, REF 5.11 =

c 0 E SANDIA WIND TUNNEL TEST. REF 5.12 A £

ICD = PARACHUTE DRAG COEFFICIENT

CD,,= DRAG COEFFICIENT WITH NO FOREBODY

0.4I

0 NEGATIVE \ BASE PRESSURE REGION

2 4 6 8 10 12 14 15 16 18 20

RATIO, LT/DB

_i SEE FIGURE 5-22 FOR DEFINITIONS.

FIGURE 5-21. Parachute Drag Loss Caused by Forebody Wake.

5-22 O

NWC TP 6575

(Reference 5.10). These measured Apollo parachute data agree well with data from the

University of Minnesota and the Cal Tech wind-tunnel tests.

Parachute wake effect data measured in wind-tunnel tests behind a 3/8 scale model of the

ejectable nose section of the XS-2 research aircraft (V)(Reference 5.11), and data measured on

model parachutes by the Sandia National Laboratories (VI) (Reference 5.12), are included in

Figure 5-21.

Figure 5-22 details the measured forebody wake effect on the 16.5-foot-diameter ribbon

drogue chute of the Apollo Command Module shown in Figure 5-21.

Many forebodies, such as aircraft, have a noncylindrical cross section. Figure 5-23

demonstrates a method that has been used successfully to convert an odd-shaped cross section

to a circular area. The area of the forebody, SB, included in the inflated area of the parachute

behind the forebody is converted into the area of an equivalent circle. The diameter of this

circle, DB, is then used as the reference forebody diameter.

f

140 I1.0 (C S)p

0 1.0 1 _o

DRAG 0 0.92 01 0 (CD S).

AREA 120 - 01 0TCDs 0 0.82 08

100- 0

FOREBODY I

DIAMETER 11.9 5.8 3.0

(FT)-

CONFIGURATION __

DESIGNATION 8/P CM PTV ICTV

VHCE BOILERPLATE PRCUEINSTRUMENTED VHCE COMMAND PARAVEHCHUE CYLINDRICAL

MODULE TETVHCETEST VEHICLE

FIGURE 5-22- Drag Lous of the Apollo 16.5-Foot-Diameter, Ribbon

Drogue Chute Caused by Different Forebodies.

* 5-23

NWC TP 6575

-/ _ INFLATED PARACHUTE DIAMETER, D O

EFFECTIVE FOREBODY AREA, SB

EFFECTIVE FOREBODY DIAMETER, DB

77,

FIGURE 5-23. Determination of Effective Forebody Diameter.

5.2.3 Measured Drag Coefficients of Various Types of Parachutes

Drag coefficients are discussed in this section for solid flat, conical, triconical,

extended-skirt, hemispherical, annular, and cross parachutes. These data were calculated

from drop tests conducted over a period of time, primarily at the El Centro test facility. The

main source for determining rates of descent were phototheodolite measurements, although

some older tests used the 300-foot drop-line method. Most of the data were collected by the

author; the summary data in Figure 5-24 were plotted by E. Ewing of Northrop-Ventura and

presented in Figure 6-35 of Reference 2.1.

Figure 5-24 plots the measured drag coefficient data for solid, flat circular, circular

conical, triconical, extended-skirt, ringsail, annular, and ringslot parachutes. The data confirm

the previously stated fact that triconical, annular, and extended-skirt parachutes have the

highest drag coefficients. The data also confirm that, similar to model parachutes

(Figure 5-16), the drag coefficients of unstable, large parachutes decrease with increasing rates

of descent.

References 5.13 through 5.20 refer to solid circular flat, circular conical, and triconical

parachutes in general, and not to any specific parachute evaluated for the drag coefficient data

in Figure 5-24.

5-24

NWC TP 6575

0

1.1

"A A Av

1-" 0.9 z

U�LLU- 0.8__

0

" 0.7

0.6

0.5 - -

15 20 25 30 35 40 50 60 70 80 90

RATE-OF-DESCENT, Veo FPS (EAS)

PARACHUTE TYPE D0 . FT Le'Do

* SOLID FLAT CIRCULAR 24-28 0.75-1.0

9 SOLID FLAT C!RrCtJLAR 100 0.95-1.0

V SOLID CONICAL CIRCULAR 95-100 0.95-1.0

A TRICONICAL 79.6-100

-- 14.3% EXTENDED SKIRT 60-67.3 0-92-1.0

" 10% EXTENDED SKIRT 56-67.2 1.0

10% EXTENDED SKIRT MC-1 35 0.85

" 10% EXTENDED SKIRT 34.5-38 0.87-0.94

"--@-RINGSAIL (XT = 7-8%) 56.2-84.2 0.94-0.97

-'•"RINGSAIL OT = 72%) 88.1 1.4

* ANNULAR (Dv/Dp = 0.63) 42-64 1.25

FIGURE 5-24. Drag Coefficient Versus Rate of Descent for Various Types of

Solid Textile Parachutes.

* 5-25

NWC TP 6575

Extended-Skirt Parachutes. Figure 5-25 shows the drag coefficient versus rate of descent 0

for various types of extended-skirt parachutes. These data are the result of numerous tests

conducted with individual parachutes. The extended-skirt parachute was developed at

Lakehurst, New Jersey, by the U.S. Navy in the late 1940s (Reference 5.21). In 1952, the U.S.

Air Force used the extended-skirt design to develop the T-10 Troop Parachute (Reference

5.22). Extended-skirt parachutes designed for recovery of the Q-2 and the USD-5 drones

achieved high drag coefficients combined with reasonably good stability of about 10 degrees of

oscillation (References 5.23 and 5.24).

1.0

0.1 94!tA..~ YBL TP

C° LEGEND

-"0SYMBOL TYPE REF

Z 0.6 FT

10% ES 38 5.23 L 10% ES 34.6 6.22

o 0.4 0 FES 71 5,23 U

0 FES 78 523

A FES 67 5.24

0.2 0 FCES 28 5.2

A EXPER 36.4 5.2

0 10% ES 34.9 5.23

0.0I I

10 16 20 25 30 35 40 45

RATE-OF-DESCENT. Veo FPS

FIGURE 5-25. Drag Coefficient Versus Rate of Descent for Various

Extended-Skin Parachutes.

Combining the high drag effect of the triconical parachute with the good stability and low

opening shock characteristics of the extended skirt design may produce a parachute

combining the best features of both designs.

The sensitivity of extended-skirt parachutes to suspension-line length is shown in

Figure 5-26. These tests were conducted with an 11.8-foot-diameter, 10% extended-skirt

parachute in the Wright Field vertical wind tunnel. The data also demonstrate the effect of

velocity on the drag coefficient.

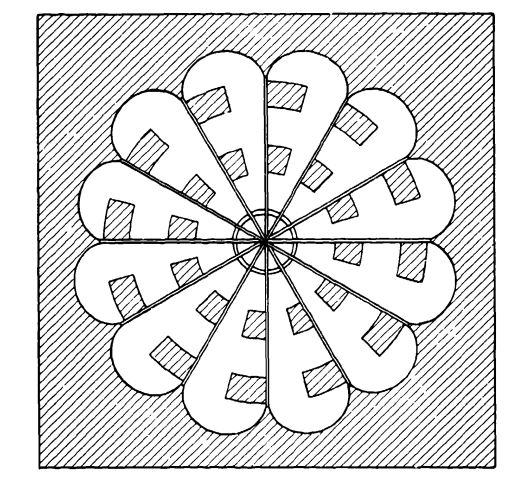

Cross Parachute. In recent years, the cross parachute has been used for aircraft and

ordnance deceleration as a low-cost replacement for the ringslot parachute. The cross

parachute was first tested in 1947 by the Naval Ordnance Laboratory (Reference 5.25) and was

reintroduced in 1%2 as the French cross parachute (References 5.26 and 5.27). The Naval

Surface Warfare Center (NSWC) at Silver Spring, Md., has conducted many aerodynamic and

5-26 0

NWC TP 6575

00

0.9-

S0.85-- . .

S0 Ve 20 FPS

,0 /Ve = 30 FPS

O 0.75.

0.65,±

'374

0.6 0.7 0.8 0.9 10 1.1 1.2 13 1.4

SUSPENSION-LINE-LENGTH RATIO, LeD 0

FIGURE 5-26. Effect of Suspension-Line Ratio on an

1.8-Foot-Diameter Extended-Skirt Parachute.

stress investigations on cross parachutes (References 5.28 to 5.32). NSWC is using the cross

parachute for the stabilization and retardation of mines, see section 8.6.4. Reference 5.33

describes the use of a cross parachute as a final descent parachute. Figure 5-27 shows the cross

parachute drag coefficient as a function of rate of descent evaluated from the NSWC

programs. This stable parachute increascs its drag coefficient witl a decreasing rate of

descent, a fact previously observed only on unstable parachutes. Drag znd stability of the cross

parachute depend on the arm's diameter-to-width ratio (W/L), on the number and length of

suspension lines, and on cloth porosity. To conform togeneral use, the nominal diameter, Do, is

used in this manual instead of the arm length to define cross parachute diameter. Reports

published primarily by the NSWC should be consulted before using this parachute.

Wind-tunnel and water-tank tow tests on cross parachutes were conducted by the University of

Leicester, England (Reference 5.34 and 5.35).

Annular Parachute. The annular parachute was developed in 1947 and named the airfoil

parachute (Reference 5.36). Figure 5-28 shows its high drag coefficient. The parachutes with

individual symbols in the figure are annular parachutes used in connection with a ringslot or

ringsail engagement parachute for midair retrieval systems (References 5.37 and 5.38).

Ribbon Parachutes. Section 5.8contains drag data on ribbon parachutes for the subsonic

and supersonic range. Ribbon parachute performance depends to a large extent on selection of

the right porosity. Design data, including the required porosity for a particular parachute size

and application, are discussed in Chapter 6. References 5.39 through 5.47, published by

various organizations, discuss performance, design details, and subsonic and supersonic

applications of ribbon parachutes.

5-27

NWC TP 6575

0.8 -9--o I® 1* *

0( 0 LD3

8 o.5

L~~~ 10"....

Z 0.6 FL /o - - - I

_____ LEGEND

TYPE Do, REFERENCE o SYMBOLS TEST FT

0.2 (0) 0 FFT 136 526

Q -- WTT 2.5 5 28/29

@ WTT 2.5 5.27

) FFT 613 5.33

0 _--1. 1

10 20 30 40 50 60 70 80

RATE -OF-DESCENT. V FPS

FIGURE 5-27. Drag Coefficient Versus Rate of Descent for Various Cross Parachutes.

12

*0

L) =LEGEND

0 SYMBOL O0 TYPE REF

< ~OF E oFT TEST

06 28 FFT 53•6

0 42 FFT 537

718 FFT 638

S • 84 FFT 67 FFT -

0 1o 15 20 25 30

RATE -OF-DESCENT. Vo FPS 0

FIGURE 5-28. Drag Coefficient Versus Ratc of Dcscent for Various

Annular Parachutes.

5-28

NWC TP 6575

"The influence of Mach number on the drag of ribbon-type drogue chutes is discussed in

section 5.8.

Ringslot Parachutes. References 5.48 and 5.49 give design details on ringslot parachutes.

A drag coefficient, CD0o, of 0.65 has been measured in free-fall tests. Selection of the proper

total porosity, in accordance with Chapter 6, is important. Ringslot parachutes used as landing

deceleration parachutes for aircraft experience a drag coefficient reduction from 0.65 to 0.60

because of the large wake behind the aircraft.

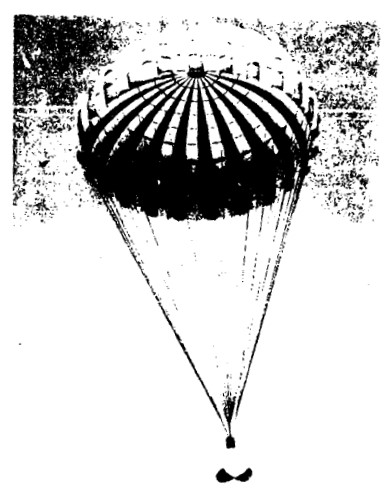

Rlngsail Parachutes. Reference 5.50 is a summary report on ringsail performance,

design, and application. These parachutes were used as the main descent parachutes for the

Mercury, Gemini, and Apollo spacecraft and for the ejectable crew module of the F-ill

aircraft.

Hemisflo Parachute. This supersonic ribbon parachute should be used at speeds of

Mach 2 or higher. References 5.51 and 5.52 provide information on the development, design,

and application of hemisflo parachutes.

Guide Surface Parachute. This parachute was developed as a high-stability, low drag

parachute for the stabilization of bombs, mines, and torpedoes. It combines good stability

with excellent damping characteristics. For details see References 5.53 and 5.54.

Disk-Gap-Band Parachute. Some information on this parachute, used successfully to

land the Viking spacecraft on the planet Mars, is contained in References 5.55 and 5.56.

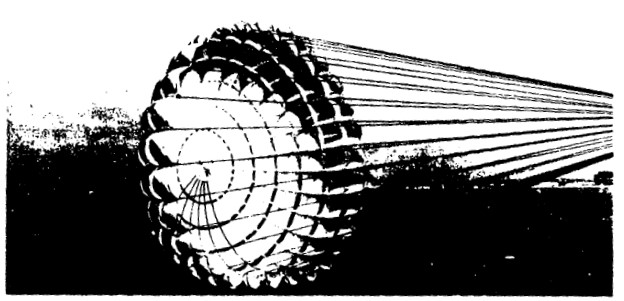

Rolating Parachutes. Several types of rotating parachutes have been used successfully.

Angled vents in the parachute canopy rotate the parachute. Centrifugal forces acting on the

canopy and suspension lines increase the projected diameter, resulting in a high drag

coefficient. Attempts to use rotating parachutes with diameters greater than 10 feet have been

unsuccessful because of deployment and canopy wrap-up problems. References 5.57 through

5.59 provide information on the three best known types of rotating parachutes.

Maneuverable (Gliding) Parachutes. Maneuverable gliding parachutes and their

performance characteristics are discussed in section 5.9.

Balloon-'yype Decelerators. These deceleration devices, including the Goodyear ballute,

are discussed in section 5.8.

5.2.4 Effect of Reynolds Number on Parachutes

Chapter 4 states that parachutes, unlike airfoils, operate in turbulent flow because of the

separation of the airflow at the leading edge of the parachute canopy. For this reason, the

5-29

NWC TP 6575

Reynolds number does not appear to change the drag coefficient of parachutes. Measured

data on parachute drag coefficient versus Reynolds number are compared in Figure 5-29 with

the known Reynolds number effect on the drag coefficient of a sphere. These data are taken

from Reference 2.1.

S~CIRCULAR DISC

0 CIRCULAR DISC

C RIGID HEMISPHERICAL

Z ^. FABRIC HEMISPHERICAL

",' 3 1 CRUCIFORM

0• 3.79:1 CRUCIFORM

SPH-ERE

105 106

Re - vD i -

FIGURE 5-.19. Effect of Reynolds Number on Drag Coefficient for a

Sphere and Various Parachutes.

5.3 STABILITY OF PARACHUTE SYSTEMS

5.3.1 General Definition

Stability may be viewed as the tendency of a body to return to a position of balance or

equilibrium after a displacement from that pe.sition. Controllability may be defined as the ease

of causing that movement, or as the effectiveness of the mechanism us,,ed to cause the body to

return to its original position. Various concepts of stability can be illustrated by simple

examples. In Figure 5-30a, a ball is shown at rest in a concave depression. A displacement of

the ball will result in gravity restoring it to its original position. This state is called "stable." If

the ball is placed on a flat surface. a displacement of the ball from its position of rest will cause

the ball to come to Test at a different location on the flat plate, with no tendency for the ball to

return to its original position; this state is termed "neutrally stable" (Figure 5-30b).

Figure 5-30c shows a ball placed in a state of equilibrium atop a larger spherical ball. Clearly,

any displacement of the small ball on the large sphere causes the ball to continuously move

away from its original position of stability. This condition is termed "unstable." In the three

simpie examples, we have considered the conditions connected with static stability.

5-30

NWC TP 6575

(a) STABLE (b) NEUTRALLY STABLE (c) UNSTABLE

FIGURE 5-30. Illustration of Static Stability.

Dynamic stability refers to the continued motion of a moving body and may be illustrated

by considering the ball on the concave surface in Figure 5-30a. The friction forces on the ball

are always in a direction opposite to its motion. The friction forces, positive damping effect,

together with the gravity component, make the ball tend to oscillate with a decreasing

amplitude until it finally achieves the illustrated position of static stability. A ball in this

dynamic environment is called "dynamically stable." If the aerodynamic forces of air

resistance and the mechanical frictional forces could be reduced to zero-an impossible

condition-there would be no damping force on the ball, and a small displacement of the force

applied to the ball would cause an indefinite oscillation of constant amplitude. Such a

condition is termed "neutrally dynamically stable." If friction force is overcome by some

external force-for example, a propulsion force-the ball would oscillate with an increasing

amplitude and would not return to its position of equilibrium; this condition is called

"dynamically unstable."

These conditions of dynamic stability are graphically illustrated in Figure 5-31, which

demonstrates the stability of three bodies. Body "a" is dynamically and statically unstable.

Body "b" is statically stable but dynamically unstable, resulting in ever-increasing oscillations.

Body "c" is dynamically and statically stable, resulting in oscillations dampened with time.

The fact that a body is statically and dynamically stable is frequently not sufficient. For

example, an automobile without shock absorbers is statically and dynamically stable in its

spring motions, but may provide an uncomfortable ride because of insufficient damping of its

body oscillations. Installation of shock absorbers increases positive damping and causes a

rapid decrease of the body oscillations with time, thereby providing a comfortable ride.

5-31

NWC TP 6575

z

0

t a

0

•5_b =e STBEUSAL

2 TIME 0

U. \Z

W STATICALLY DYNAMICALLY

a = UNSTABLE UNSTABLE

b - STABLE UNSTABLE

c = STABLE STABLE

FIGURE 5-31. Graphical Illustration of Dynamic Stability.

A statically stable parachute may require excessive time to decrease its oscillation after

an external disturbance, such as a wind gust, indicating that the parachute's damping

characteristics are inadequate for stabilizing an unstable body.

In the case of an aircraft, good static and dynamic stabilities are desirable for large

cargo-type aircraft, but this stability counteracts fast changes in attitude and position required

for fighter aircraft, which are generally built with low or neutral static stability. In recent years,

aircraft requiring a high degree of mobility have been designed with a slightly negative static

stability, thus increasing mobility and decreasing the size and drag of the control surfaces.

S.3.2 Parachute Stability

Stability is defined as the tendency of a body to return to a position of equilibrium after

displacement. Parachute engineers frequently use the term stability loosely. If two airdrop

platforms descend, each on a 100-foot-diameter parachute, and one parachute oscillates * 30

degrees and the other ± 5 degrees, observers frequently call the former parachute system

unstable and the latter stable. In reality, both parachute systems are statically unstable in the

oscillating mode but are sufficiently dampened dynamically to stay within their ranges of

oscillation without increasing the oscillation amplitude. It is more precise to define these

parachutes as oscillating ±30 degrees or ± 5 degrees; and, if possible, to state that

5-32

NWC TP 6575

0 disturbances such as those caused by wind gusts are dampened within a given number of full

oscillations. The parachute oscillating + 5 degrees most likely meets the requirements for

airdrop; however, the same parachute is unsuitable for stabilizing airdropped bombs or

torpedoes. For this application, a parachute with zero oscillation and good damping is

required. As defined later in this section, a parachute meeting this requirement has a steep

negative dC./dc over a wide range of angles of attack.

Why should one parachute have no oscillation and strong damping characteristics while

another parachute oscillates violently? Figure 5-32 explains this difference by showing the

airflow around several types of parachute canopies and rigid hemispheres. The airflow, made

visible with smoke ejected from equally spaced nozzles in front of the parachute models, acts

as streamlines, as explained in Chapter 4. Figure 5-32a shows the airflow around an imporous

hemisphere. Airflow cannot get through the canopy but goes around and separates on the

leading edge of the hemisphere in alternating vortexes, forming what is called the Karman

-------------------------- / ,-

KARMAN VORTEX

TRAIL

-- . .... M- ---(SOLID CIRCULAR)_

N 8

ATTACHED FLOW IN

(A) IMPOMOUS CANOPY. INSTAGILITY CAUSRO 9V SIDE PONCI. N. ft

FLOW SEPARATION (d) POAOUSCANOPY. STABILIZING MOMENT, 0 * A * N ft *

.2 • UNIFORM

- . .. --. , WAKE LARGE PROJECTED AREA _ (RIBBON)

FLOW SEPARATION DRAG 0

(I) POROUS CANOPY. NO SDoE FORC1. NO UN&TAILE MOMCMT. -A

•_ FLIOý% SEPARATION M) CANOPY WITH SCOIAMAAION 9001, STAWlLIZlNO MOhMINT,

-FLOVV SEPARATION

Ic) CANOPY WITN SEPARATION LOGE (OGUIOD URFAC1).

No SIOID POAC. NO UNITABLe MOMENT.

FIGURE 5-32 Relationship of Airflow and Stability for Various Parachutes.

0 5-33

NWC TP 6575

Vortex Trail. The separation causes alternate pressure areas on opposite sides of the canopy,

and these pressure areas produce the parachute's oscillations.

Figure 5-32b shows the effect of openings in the canopy. Part of the air flows through the

canopy and forms a uniform wake consisting of small vortexes. In addition, the airflow

separates uniformly around the leading edge of the canopy, eliminating the destabilizing

alternate flow separation of the Karman Vortex Trail. Uniform wake and airflow separation is

the principle of the ribbon parachute and all slotted parachute canopies.

The guide surface parachute (Figure 5-32c) has a sharp separation edge around the skirt

of the canopy, creating a strong, uniform airflow separation around the leading edge. In

addition, the inverted leading edge (guide surface) creates a large, stabilizing normal force.

Both the normal force, N, and the drag force, D, create a stabilizing moment if the parachute is

displaced from its zero-angle-of-attack position (Figure 5-32e). The known main design

features for creatingstable parachutes are uniform airflow separation around the leading edge

of the canopy, airflow through the canopy, and a large restoring moment such as that generated

by a guide surface.

The static stability of various parachutes has been measured numerous times in

wind-tunnel tests. Figure 5-33 plots the moment coefficient of several parachute types and of

rigid hemispheres, as measured by the University of Minnesota (References 5.60 and 5.61). A

negative dCm/da of the moment coefficient curve indicates that the parachute is stable and

will return to its zero-angle-of-attack position after a disturbance. The solid, flat. circular

canopy is a typically unstable parachute. It will oscillate between k 25 degrees, but if deflected

more than 25 degrees it will return to the 25-degree position. The ribbon and guide surface

parachutes will return to their zero-angle-of-attack attitude if displaced, as indicated by the

negative slope of the dCm/dct curve going through the zero-angle-of-attack position for both

parachute types.

The guide surface parachute has the steepest dCm/dc, and, therefore, the strongest

stabilizing moment and best damping characteristics of all known parachutes.

Larger parachutes oscillate less than small parachutes. A 3-foot-diameter solid flat

circular parachute manufactured from standard 1.1-oz/y 2 ripstop material, tested in a wind

tunnel, will oscillate about ± 35 to 40 degrees. The standard 28-foot-diameter personnel

parachute oscillates about ± 30 to 35 degrees. The 100-foot-diameter G-11 cargo parachute

oscillates about 10 to 20 degrees. The 200-foot-diameter cargo parachute manufactured from

1.6-oz/y 2 material with about the same porosity as the other parachutes (described in

Reference 5.14) oscillates less than 5 degrees. Ludtke discusses oscillation problems in

Reference 5.62.

5-34 0

NWC TP 6575

RIGID HEMISPHERE WITH

35% GEOMETRIC POROSITY

0.4

GUIDE SURFACE PARACHUTE

NOMINAL POROSITY:

100 FT 3 /FT 2 /MIN

0.3

E

1-: 0.2 SOLID FLAT PARACHUTE

Z NOMINAL POROSITY:

2_ 100 FT 3

/FT 2 /MIN

U.

ILLU

0

L) 0.1

I�z

0

+

RIGID HEMISPHERE

0.1 NONPOROUS RBO AAHT

Cm RELATED TO PROJECTED 28%BO GEMERICALT

AREA AND MOMENT CENTER POROSITY

1.33 D P BELOW CANOPY SKIRT

I I I I I I I I I 1

-70 -60 -50 -40 -30 -20 -10 +10 +20 +30 +40 +50

ANGLE OF ATTACK,a, DEGREES

NOTE: IN THE U.S. A STABILIZING MOMENT IS DEFINED

AS HAVING A NEGATIVE dCm/da. IN EUROPE, A

STABILIZING MOMENT IS DEF:NED AS HAVING

A POSITIVE dCm/da.

FIGURE 5-33. Moment Coefficients Versus Angle of Attack for Guide Surface; Ribbon;

and Flat, Circular Parachutes; and for Porous and Nonporous Hemispheres.

0 5-35

NWC TP 6575

5.3.3 Stability of a Parachute Body System

Parachutes that are used with stable air vehicles must also be stable and not interfere

with the inhercnt stability of the vehicle. Parachutes with good stability and high drag are used,

such as the ribbon, ringslot, and cross parachutes. If a fast-falling, unstable body must be

stabilized while maintaining a high rate of descent, a parachute with a strong negative

dCm/do,, such as a guide surface parachute, may be preferable. For each parachute assembly,

a compromise between required stability, weight, volume, and cost determines the final

selection.

The following parachute application ranges have been established based on many years

of practical experience.

Aircraft Landing Deceleration. Aircraft are inherently stable and do not require aircraft

landing deceleration parachutes to contribute to their stability. Therefore, high drag stable

parachutes that do not interfere with the aircraft controllability are used. Ribbon, ringslot, and

cross parachutes are used primarily for aircraft landing deceleration.

Bomb Stabilization. During World War II, the Germans developed parachute-stabilized

bombs that enabled them to shorten the length of the bomb and to store more bombs in

existing aircraft bomb bays. These fast-falling bombs required a low drag, highly stable

parachute with good damping capability to obtain the desired stability. The guide surface

parachute was developed specifically for this application as a low drag, high-stability

parachute (Reference 5.53). A single riser attachment did not provide a sufficiently stable

parachute-bomb system, and a more rigid connection between the bomb and the parachute

was required. Figure 5-34 contains two examples of rigid parachute-bomb connections: the

multiple-point attachment on the circumference of the bomb and the geodetic attachment.

The geodetic attachment is the best solution but is more complex.

Torpedo and Mine Stabilization. Mines and torpedoes that are airdropped from low

altitudes are equipped with retardation parachutes to

1. Decelerate the store to an acceptable water entry velocity, generally below 200 ft/s.

2. Obtain a water entry angle that avoids ricochet.

3. Avoid store oscillation and associated store damage at water impact.

Guide surface, ribbon, ringslot, and cross parachutes are being used successfully for this

application.

Bomb Retardation. Bombs dropped at high speeds from low-flying aircraft must be

retarded to

1. Obtain a steep impact angl, to avoid ricochet.

2. Permit the aircraft to escape the effective range of the exploding bomb.

3. Obtain a good fragmentation pattern associated with a steep impact angle.

5-36 0

NWC TP 6575

S

BOMBS

(a) SINGLE POINT (b) MULTIPLE POINT (c) GEODETIC

* AIRCRAFT CREW MODULES

(d) CENTER LINE (e) MULTIPLE POINT (f) SINGLE POINT

CG ATTACHMENT CG ATTACHMENT

FIGURE 5-34. Various Conrigurations of Parachute Vehicle Attachments.

5 5-37

NWC TP 6575

Stable parachutes with good drag characteristics used for this one-time application

include ribbon, ringslot, and cross parachutes as well as the inflatable ballute-type retarders.

Fjection Seat, Encapsulated Seat, and Crew-Module Stabilization and Retardation. All

three aircraft escape systems need parachutes for stabilization and retardation. Stabilization

is required in pitch, yaw, and roll; parachutes can provide stabilization in pitch and yaw, but

are poor for roll control. For descent from a high altitude, a roll control of not more than 2 to 3

rpm is necessary for aviator comfort. This control can be obtained with a relatively large

drogue chute with an equivalent sea-level rate of descent of 120 to 150 ft/s.

The aircraft crew-module stabilization in Figure 5-34 demonstrates the problem of

stabilizing an asymmetrical body with the center of gravity (CG) off the center line of the

vehicle. In the example shown, the drogue chute had to be attached offset to the nose section of

the XS-2 research aircraft to ensure that the parachute force line would run through the CG of

the crew module with the module hanging at a -2 degree zero lift attitude to eliminate

destabilizing side forces (Reference 5.11).

The stability relationship of parachute and forebody is quite complex in systems where

unstable forebodies must be stabilized by minimum size parachutes. Both the forebody and

the parachute can oscillate in a 360-degree plane. The stability of such two-body,

multi-degree-of-freedom systems has been investigated by several authors (References 5.63

through 5.67).

Neustadt showed that deploying a parachute opposite the oscillating motion of the

forebody may increase the parachute force by as much as 20% (Reference 5.68).

S.4 PARACHUTE INFLATION PROCESS

5.4.1 Opening Force Investigations

Many attempts have been made to develop theoretical solutions to the parachute

inflation process and obtain quantitative values for opening time and force. Investigations by

Mueller, Scheubel, O'Hara, Rust, Heinrich, Wolf, and Purvis, defined in References 5.69

through 5.75, have increased the understanding of the parachute opening process, including

the effect of apparent mass. However, no satisfactory practical solution for calculating filling

time and parachute opening forces has evolved. The analytical solution of the opening process

has been complicated in recent years by the development of means for controlling parachute

inflation, such as reefing, sliders for steerable parachutes, pull-down vent lines, and related

devices. While these methods provide control of parachute inflation, and thereby the opening

forces, they also interfere with the parachute's natural inflation process. A good account of the

present status of the parachute inflation theory was presented by D. Wolf in 1982 during the

University of Minnesota Short Course on Parachute Systems Technology (Reference 2.17).

5-38

NWC T? 6575

In 1942 Pflanz developed a numerical method for calculating parachute opening forces

(References 5.76 and 5.77). He assumed that the drag area of the parachute or of any drag

device increased from a low value to 100% in a given time and in a mathematically definable

form, such as convex, concave, or linear. The parachute filling distance was assumed to be

constant for a specific parachute. The Pflanz method includes altitude effects but does not

include gravity effects or drag area overshoot after full opening.

Schuebel was the first to investigate the effect of the apparent mass on the parachute

opening process. He defined apparent mass as both the air mass inside the inflating canopy

and the air mass outside the canopy that is affected by the inflation process (Reference 5.70).

Modern, high-speed computers make it possible to calculate the time-dependent

force-velocity-trajectory history of the parachute opening process for complex recovery

systems. This calculation was first accomplished in 1960 by Space Recovery Systems, Inc.

(Reference 5.23). The computer results agreed well with the forces measured in free-flight tests.

This force-velocity-trajectory approach was used in an extended form for predicting the

parachute opening forces of the Gemini and Apollo drogue and main parachutes (References

5.78 and 5.79). McEwen gives an excellent review of previous efforts and recommends that

inflation distance, not inflation time, be used as the reference for the inflation process.

For a parachute-vehicle system moving in space (Figure 5-35), the trajectory equations

can be written in the form shown in the figure.

dv -F-Dr +Wv SINO

dt My

dO -g COS 0

dt V

(F + DO)

FIGURE 5-35. Angle and Force Relationships for a Deceleration

System Moving in Space.

The parachute force, F, as a function of time is

(m + m p)4 dv - +v- dm, + WvsinO

(CDS)pp/2v 2 + -mp)

5-39

NWC TP 6575

where

F - parachute force acting parallel to the flight trajectory, lb

D, - drag of the vehicle (payload), lb

Wv - weight of the vehicle or payload, lb

0 - trajectory angle against the horizontal, degrees

S - deceleration of gravity, ft/s2

(CDS)p - parachute drag area, ft2

p - density of air, slugs/ft3

v = trajectory velocity, ft/s

ma - apparent mass (added mass), slugs

mp = mass of parachute, slugs

mv - mass of the vehicle or payload, slugs

Wp = weight of the parachute, lb

The drag of the vehicle, Dr, depends on the drag area of the vehicle and on the

instantaneous dynamic pressure, which changes during the opening process of the parachute.

The trajectory angle, 0, changes from the launch or deployment angle to vertical most

rapidly during and after urachute inflation.

Changes in the value of the acceleration of gravity, g, do not affect the outcome at

altitudes below 100,000 feet.

The parachute drag area, (CDS)p, increases from close to zero at line stretch to 100% at

full open canopy.

Density, p, changes with altitude; this change must be considered for longer trajectories.

Both parachute and payload are assumed to have the same velocity and the same trajectory

angle.

The apparent or added mass, ma, is calculated by multiplying volume by density and by a

form factor that depends on the particular parachute type. The apparent mass at an altitude of

40,000 feet is only one-quarter of the apparent mass at sea level, because apparent mass

depends on density. Therefore, the apparent mass affects the magnitude of the parachute

opening force at a given altitude.

5-40

NWC TP 6575

0 In the parachute force equation, the vehicle weight is Wv • sin 0. Using the sign

convention of Figure 5-35, a parachute opening in a vertical attitude will have a force that is one

unit weight higher than the force of a parachute opening in a horizontal attitude. This force

difference must be considered in planning parachute test programs.

5.4.2 Parachute Canopy Inflation

Parachute inflation is defined as the time interval from the instant the canopy and lines

are stretched to the point when the canopy is first fully inflated. Figure 5-36 shows the phases of

canopy inflation. The canopy filling process begins when canopy and lines are stretched and

when air begins entering the mouth of the canopy (a). After the initial mouth opening, a small

ball of air rushes toward the crown of the canopy (b). As soon as this initial air mass reaches the

vent (c), additional air starts to fill the canopy from the vent toward the skirt (d). The inflation

process is governed by the shape, porosity, and size of the canopy and by air density and

velocity at the start of inflation. Inflation is slow at first but increases rapidly as the mouth inlet

of the canopy enlarges (e) and the canopy reaches its first full inflation (f). Most solid textile

canopies overinflate and partially collapse because of the momentum of the surrounding air

(g). Several factors contribute to an orderly, repeatable inflation process and to a low, uniform

(a) OPENING OF CANOPY MOUTH

* (b) AIR MASS MOVES ALONG CANOPY

S(c) AIR MASS REACHES CROWN OF CANOPY

(d) INFLUX OF AIR EXPANDS CROWN

(TYPICAL REEFED INFLATION SHAPE)

(e) EXPANSION OF CROWN RESISTED BY

STRUCTURAL TENSION AND INERTIA

if) CANOPY REACHES FIRST FULLY INFLATED

STAGE

(g) SKIRT OVER-INFLATED, CROWN DEPRESSED

BY MOMENTUM OF SURROUNDING AIR MASS

FIGURE 5-36. Parachute Canopy Inflation Process.

0 5-41

NWC TP 6575

opening force. The amount of air moving toward the canopy vent at point (b) should be small to

avoid a high-mass shock when the air bubble hits the vent of the parachute. The inflation of the

canopy should occur axisymmetrically to avoid overstressing individual canopy parts.

Overinflation of the canopy after the first initial opening should be limited to avoid delay in

reaching a stable descent position.

Methods have been developed to control the inflation of the canopy; the most frequently

used is canopy reefing. Reefing stops the inflation of the canopy at one or more steps between

stages (c) and (0), thereby limiting the parachute opening force to a preselected level.

Retfing is also required for uniform inflation of parachutes in a cluster. Stopping the

inflation of all cluster parachutes at a point close to stage (d) of Figure 5-36 allows all

parachutes to obtain an initial uniform inflation-a prerequisite for a uniform final

inflation--without running into a lead/lag chute situation with widely varying parachute

forces. Other means for controlling the parachute opening include ballistic spreader guns,

sliders for gliding parachutes, and pull-down vent lines.

5.4.3 Canopy Inflation Time

Knowledge of the canopy filling time, defined as the time from canopy (line) stretch to the

first full open canopy position, is important. Mueller and Scheubel reasoned that, based on the

continuity law, parachutes should open within a fixed distance, because a given conical column

of air in front of the canopy is required to inflate the canopy (References 5.69 and 5.70). This

fixed distance is defined as being proportional to a parachute dimension such as the nominal

diameter, DO. This assumption was reasonably confirmed in early drop tests with ribbon

parachutes. French and Schilling, in papers published in 1968 and 1957, confirmed this

assumption (References 5.80 and 5.81). Using the fixed-distance approach and the definitions

in Figure 5-37, the filling distance for a specific parachute canopy can be defined as

sf = n Dp - constant.

With sf = n DP` the canopy filling time, tf, can be defined as shown in Figure 5-37.

sf = n D P

FIGURE 5.37. Filling Distance of a Parachute Canopy.

5-42 0

NWC TP 6575

Because the parachute diameter, Dp, is variable, the fixed nominal diameter, Do, is used

to calculate canopy filling time

n D.

V

where

Do is the nominal par,,iiute diameter, feet

v is the velocity at line stretch, ft/s

n is a constant, typical for each parachute type, indicating the filling distance as a

multiple of Do, dimensionless.

The constant, n, will be called "fill constant" in subsequent discussions. The basic

filling-time equation, tf - n Do/v, has been extended by Knacke, Fredette, Ludtke, and others.

The following formulations have provided good results.

Ribbon Parachute

tf- D•.

where n - 8 (Knacke).

This equation gives accurate results with ribbon parachutes when the canopy porosities

recommended in Chapter 6 are used. For small-diameter ribbon parachutes investigated in

high-speed sled and rocket tests, Fredette found the following relationship:

tf = 0.65ATDo v

where XT is the total canopy porosity expressed as a percent of the canopy surface area, So.

Solid Flat Circular Parachute

Wright Field investigations resulted in the following formulations:

nDo tf M= n-D V0.85

where n - 4.0 for standard porosity canopig, and n = 2.5 fe. low porosity canopies.

0 5-43

NWC TP 6575

Cross Parachute

An investigator at NSWC, Silver Spring, Md., recommends

. (CDS)pn

where n - 8.7. The author has evaluated parachute fling-time data from free-flight tests and

found that a formulation for filling time, where the line-stretch velocity, vs, is a linear function

instead of an exponential function, gives satisfactory results in the medium-velocity range of

about 150 to 500 ft/s. Table 5-6 lists the fill constant, n, in the equation tr -nD for a variety of v

parachutes.

TABLE 5-6. Canopy Fill Constant, n, for

Various Parachute lypes.

Canopy fill constant, n

Paraxe type Res DWW Unreeofe

opening opening opening

Solid flat circular ID& ID a

Extended-skIrt, 10% 16-18 4-5 10

Extenled-skirt, full 16-18 7 12

Cross ID ID 11.7

Ribbon 10 a 14

Ringslot ID ID 14

Rlngsall 7-8 2 7

Ribless guide suudace ... ... 4-6

a ID = Insufficient data available for meaningful

evaluation.

Additional fill-factor data can be found in Table 6-1 of Reference 2.1.

The filling time of the various stages of reefed parachutes can be determined as follows:

Do (CDS)R 1and t 5-4 - nD (CDS)o - (CDS)R 1/2

Vs (CDs), Vt (CDS)o

5-44

NWC TP 6575

where

tf, and tf2 are the reefed and disreefed filling times,

vs and Vr are the velocities at line stretch and at disreef, ft/s

(CdS)R and (CdS)o are the reefed- and full-open drag areas, ft2.

Some solid textile, circular parachute types appear to have a critical opening velocity. At

high velocities and high dynamic pressures, the canopy opens only partially. The drag of the

partially opened parachute decelerates the parachute-vehicle system and the canopy opens

fully. This type of opening can also occur on ribbon parachutes with porosities that are too

high (Figure 6-23). Attempts to use this phenomenon for controlling the canopy inflation

process, and thereby the parachute forces, have not been successful because of the variables

involved and the difficulty of controlling the porosity of solid fabric canopies.

Some types of ribbon parachutes have been opened in the velocity range of up to Mach

4.0. Greene concludes that canopy filling time at supersonic speeds is constant, because the

canopy operates behind a normal shock. Reference 5.82 presents test data that appear to

confirm his investigations.

In a NASA test program to develop parachutes for planetary landing, ringsail, cross, and

disk-gap-band parachutes were opened successfully at altitudes above 100,000 feet and at

speeds exceeding Mach 3.0. Section 5.5 provides further details on high-altitude effects, and

section 5.8 describes supersonic parachute applications.

5.4.4 Parachute Drag-Area Increase During Canopy Filling Process

The parachute drag area, (CDS)p, increases from 0 to 100% during canopy inflation. The

drag-area-versus-time increase--linear, convex, concave, or random-is well known and has

proven to be constant and repeatable for known parachute types (see Figure 5-38).

The drag-area-versus-time increase for reefed ribbon, ringsail, and extended-skirt

parachutes is shown in Figure 5-39.

RIBBON RINGSLOT CIRCULAR EXTENDED

1 7

l - , . k- t - tf1- t

FIGURE 5-38. "lypical Drag-Area-Versus-Time Increase for Various Parachute ypos.

5-45

NWC T? 6575

RIBBON EXTENDED RINGSAIL

C./1/1 /

,, I - I I.. . ,

FIGURE 5-39. lypical Drag-Arca-Verws-Time Increase for Reefed Parachutes.

The shape of the drag-area-versus-time curve may be somewhat drawn out or

compressed by reefing, changes in porosity distribution in the canopy, wide slots, or other

means; however, the basic configuration of the curve is maintained for a particular type of

parachute.

Drag-area-versus-time curves are obtained from wind-tunnel or free-flight tests by

dividing the measured instantaneous force by the instantaneous dynamic pressure. This, more

precisely, should be called a dynamic drag area, because it includes characteristics that affect

the opening process, such as apparent mass and altitude density.

The evaluated drag-area-versus-time increase for unreefed, solid flat circular, ringslot,

and personnel guide chutes (Figure 5-40), is taken from Reference 5.83. The author has added

the typical drag-area increase for ribbon and extended-skirt parachutes, determined from

numerous tests. Ribbon and ringslot parachutes have a strictly linear drag-area-versus�time increase, and solid textile parachute types have a rather uniform, concave form of

drag-area increase. Ludtke found that this increase of solid textile parachutes could be

expressed by

(CDS)X r I

(CIDS), Vf

where q is the ratio of the projected mouth area of the canopy at line stretch to the projected

frontal area of the fully opened canopy.

Figure 5-41 plots drag-area increase for the 63-foot-diameter reefed ringsail main

parachutes used with the Mercury space capsule. It shows a typical characteristic of ringsail

parachutes-the increase in drag area during the reefed stage. The ringsail parachute inflates

rapidly into an initial reefed stage and then grows slowly through inflation of additional rings.

This characteristic is advantageous for single parachutes because it constitutes a form of

continuous disreefing, a highly desirable feature.

5-46

NWC 1? 6575

20

0 1

I S PERSONNEL GUIDE SURFACE

o RINGSLOT CANOPY

L ELLIPTICAL CANOPY

1.6 0 SOLID FLAT CANOPY

o 10% EXTENDED SKIRT

1.4 V RIBBON

o 1.2

0.."

0/

Deo

002

0.

Ii

0.GUR 5c40 DrgAe.atoVru/imninesFiln ie

• ' / 0

g , /

0.4/ / /

000

0 0.2 0.4 06 08 1 0 1.2 14 1

t, t

S~FIGURE 5.40. Drag-Area Ratio Versus Dimensionless Filling Time.

400- 2000

A = POINT OF MAXIMUM REEFED FORCE

B - POINT OF MAXIMUM DISREEF FORCE

300 N

E,

1 ISREEF, I SCALE .

1400 2000

0 -

A

w

300 10 2

,R 5 a o i 200 1000

uJIU

0 O 20 30 40 50 60 70 80 9L

TiME SECONDS

FIGURE 5-41. Drag-Area-Venus-Time Diagram for the Mercury 64-Foot Ringsail Parac'hute.

0 5.47

NWC TP 6575

Figure 5-41 also demonstrates the extremely short disreefing time of 0.8 second.

References 5.50 and 5.79 include figures that show the drag-area increase for a single 85-foot�diameter Apollo ringsail main parachute. The increase in drag area during the reefed stage

proved detrimental for the cluster of the three Apollo main parachutes because it tended to

support nonuniform inflation.

Reference 5.23 gives drag-area-versus-time data for reefed, extended-skirt parachutes.

Several Sandia Reports (References 5.41 to 5.47) provide data on ribbon parachutes.

Drag-area-versus-time increase for a 101-foot-diameter, triconical parachute is shown in

Figure 5-42. The drag area in the reefed stage remains constant, which is typical for all known

types of parachutes except the ringsail. As shown in Figure 5-40, the disreef drag-area curve

displays the same concave shape as other solid textile parachutes. The triconical parachute, in

contrast to the ringsail parachute (Figure 541), has a long disreef time (tf2 = 7.5 seconds),

resulting in a relatively small canopy overshoot.

Data on drag-area-versus-time increase for the various parachute types are important

for establishing the drag-area-versus-time diagrams required for the force-time-trajectory

computer program described in this section and used in Chapter 7.

360 9000

F

320- -P 8000 -F

SREEFEDu 280 - 7000 -IREEF 1 wu 13 DISREEF cc

S240 - 6000 ,

S200- 5000 o -

Q 160- 4000 - .L_

wr U I "0120- ` 3000 -

"LL so- 0 2000

40- 1000- tr SEC- - f2

O 0 I I _

0 2 4 6 8 10 12 14 16 18 20 22 24

TIME, SECONDS

FIGURE 5-42. Drag-Area-Versus-Time Diagram for a Reefed

101-Foot-Diameter Triconical Parachute.

5-48

NWC TP 6575

Recovery system engineers should evaluate and publish drag-area-versus-time diagrams

to improve the database for computing the force-trajectory-time analysis of parachute

recovery systems.

S.4.5 Effect of Canopy Loading, W/(CDS)p, on Parachute Opening Forces

Figure 5-43 is a force-time diagram of a parachute opening in a wind tunnel. This pattern

is typical for parachutes without velocity decay during parachute inflation and is called the

"infinite mass" condition, because the parachute acts as if it were attached to an infinite mass.

The same parachute dropped from an airplane and weighted for a 20 ft/s rate of descent

will have the known force-time diagram of a personnel parachute (Figure 5-44).

The personnel parachute dropped from an airplane has a finite load and is referred to as

being tested, or used, under a "finite mass" condition. The primary difference between infinite

and finite mass conditions is that, under infinite mass conditions, the velocity does not decay

during parachute opening; whereas, under finite mass conditions, the velocity during

• "-Fx /Fc

F S Cx = Fx xl Fc

FIGURE 5.43. Parachute Force Versus Time for a Wind-Tbnnel Test (Infinite Ma&.- Condition)

/Fx

FIGURE 5.44. Force Versus Time for a Personnel

Parachute Drop (Finite Mass Condition)

"-49

NWC TP 6575

parachute opening decreases substantially. Infinite and finite mass conditions can also be

defined as conditions of high and low canopy loading, W/(CDS)p.

An additional typical difference between infinite and finite mass conditions is the

location of the peak opening force, F.. For a parachute opened under infinite mass conditions,

or high canopy loading, peak opening force occurs at the first full canopy inflation. The peak

opening force of a parachute opened at a finite mass condition will occur long before the

parachute canopy is fully open.

The relationship of the peak opening force, F., to the steady-state drag force, F., in

wind-tunnel tests is defined as

Opening-force coefficient, C, , = (see Figure 5-43).

C, is a constant for a specific parachute type, as shown in Tables 5-1 through 5-5.

With the newly defined opening-force coefficient, C,,, the equation for the parachute

force can be written

F, = (CDS)p q Cx X,

where

(CDS), = the drag area of the fully open parachute, ft2

q = the dynamic pressure at line (canopy) stretch, lb/ft2

C,- = the opening force coefficient at infinite mass, dimensionless

X1 = opening-force-reduction factor, dimensionless.

The force-reduction factor, X1, is 1.0 for a parachute opened at the infinite mass

condition; close to 1 for high canopy loading drogue chutes (close to the infinite mass

condition); and as low as 0.02 for final descent parachutes with a low canopy loading (finite

mass).

Table 5-7 shows the difference in opening forces and X1 factor for a 28-foot-diameter

parachute opened at 180 KEAS behind an aircraft as a landing deceleration parachute; behind

an ordnance device such as a bomb, mine, or torpedo for retardation; and as personnel

parachute for an aviator. The difference in the force reduction factor X1 for the three

applications is surprising. The primary reason for this effect is the difference in velocity decay

during the parachute opening process.

Figure 5-45 shows the force-time record of a 15.6-foot-diameter ringslot parachute

opened behind a B-47 bomber at a 30,000-foot altitude. This parachute, used as an approach

brake for descent from high altitude, has a canopy loading close to infinite mass condition,

resulting in an X, factor of 1.0.

5-50

NWC TP 6575

TABLE 5-7. Opening Forms and Canopy Loading of a 28-Foot-Diameter

Parachute for Various Vehicle Applications.

Vehicle Mass

AppliCatkon welght, Ib (CoS)P, ftz W/(C0 S)P, llMft 2 Cx Fl, Ib X, condition

Aircraft 140,000 490 286 1.7 91,200 1.0 Infinite

Ordnance 2000 490 4.1 1.7 30.100 0.33 Intermedlate

Petonnel 250 490 0.51 1.7 2900 0.032 Finite

180 9000 AIRSPEED

160 8000 x

Fx =7,400 LB•._

140 - 7000 -

u, 120 0 6000- F 6,800B

5 z B-47 APPROACH PARACHUTE 100- 0 5000-

0. TEST DATE: 5 MARCH 1954

I- . 15.6-FT-DIA RINGSLOT PARACHUTE

Q 80 - 4000 - DEPLOYMENT ALTITUDE. 30.000 FT 0 Cr "J 0 AIRCRAFT WEIGHT 128.000 LB

60- -- 3000 NCANOPY LOADING W (CD'S)o 2 1365 PSF

I F. = 7,400 L8, F, - 6.800 LS

40 - 2000 - F Cx .• 1 088, x I - 1.0

7-c

20- 1000 tf -- CDo .49

0 0 oF_ __ __I _I _ l 1 2 3 4 5 6 7

TIME AFTER COMPARIA -.NT DOOR OPENING, SECONDS

FIGURE 5-45. 15.6-Foot-Diameter Ringplot B-47 Approach Parachute Opening Forces.

The clean, aerodynamic configuration of the B-47 bomber produced a shallow approach

angle, making a point landing difficult. A 15.6-foot-diameter ringslot parachute was used

instead of wing brakes or spoilers to increase the drag on approach and thereby steepen the

glide angle. At touchdown, a 32-foot-diameter ribbon parachute was deployed as a

deceleration parachute side-by-side with the ringslot parachute. Deploying the parachutes at

even skirt levels assured successful opening of the second parachute. Note that the aircraft

velocity does not decay during parachute inflation.

Figure 5-46 shows the opening process and the opening force versus time for a

29-foot-diameter, guide surface personnel parachute tested at 250 knots at the El Centro,

Calif., whirl tower. The difference in the force-versus-time diagram, with the ringslot

0 5-51

NWC TP 6575

LEGEND

A = DROP

8 z CANOPY LINE STRETCH. F,

C = MAXIMUM PARACHUTE FORCE. F 3.740 LB

D CANOPY HALF INFLATED

E = FIRST FULL CANOPY INFLATION

4,000

C

3.000

2.,2000

0

UIf

0.1 0.2 0.3 04 05 06 0.7 08 09 10 TIME. 11 SEC1.2 1.3 1.4 15 16 17 18 1.9 20 21 22

FIGURE 5-46. Opening Proess and Opening Forme Venus Time for a Guide Surface Personnel Parachute

Tested at the El Centro Whirl Tower at 250 Knots With a 200-Pound Torso Dummy.

parachute opened behind the B.47 aircraft, is obvious. The maximum opening force, F1,

occurs when the parachute canopy has reached about one-third of its inflated diameter. The

force at full open canopy has decreased to about 600 pounds, indicating that parachute

velocity during opening has decreased almost to equilibrium velocity. The velocity decay

during opening results in an opening-force-reduction factor, X1. of 0.0239.

Another important characteristic is the relative size of the snatch force. On high canopy

loading parachutes, where the parachute mass is small compared to the mass of the vehicle to

be decelerated, the snatch force is small if the deployment system is good, as described in

Chapter 6. On low canopy loading parachutes, where the mass of the parachute can be 3 to 7%

of the mass to be decelerated, the snatch force can reach or surpass the maximum opening

force unless a proper deployment method is used.

All parachute applications fall into distinctive groups of canopy loading, W/(CDS)p.

Canopy loading is equivalent to dynamic pressure at equilibrium velocity and therefore relates

to rate of descent. Figure 5-47 shows this relationship.

5-52 0

NWC TP 6575

10009"

500

400

S300

200

LU 100 200 500 1000 1500

L" 100 (•I PERSONNEL & CARGO

LL PARACHUTES

U MISSILE MAIN RECOVERY

L, ;l PARACHUTES

U- 5

•: 4 •,•.• rM ORDNANCE PARACHUTES 40

er17 SUBSONIC MISSILE DROGUE

3• CHUTES

A Y A G S V LANDING DECELERATION 13 PARACHUTES

20 MZ SUPERSONIC MISSILE

DROGUE CHUTES

I LANDING APPROACH

•/ PARACHUTES

0.1 0.5 1.0 5.0 10 50 100

•. CANOPY LOADING W/CDS)p, PSF

FIGURE 5-47. Rate of Descent Versus Canopy Loading and Parachute Applications.

The seven application groups in Figure 5-47 can be combined into three groups in

relation to the force-reduction factor, X1. Groups I and II will have X1 factors in the 0.02- to

0.25-range (personnel and cargo) parachutes. Group III (ordnance) parachutes have X1

factors in the 0.3 to 0.7 range. These parachute groups operate at finite mass conditions. All

parachutes in Groups IV to VII have X1 factors close to or equal to 1.0 and operate at infinite

mass conditions.

5.4.6 Methods for Calculating Parachute Opening Forces

Three methods for calculating parachute opening forces are discussed in this section.

Method I, the W/(CDS)p method, is fast but should be used for preliminary calculations only.

Method 2, the Pflanz method, is mathematically exact and provides good results within certain

application limits. Method 3, the previously mentioned computerized force-trajectory-time

method, gives good results with no limitations. However, all three methods require knowledge

of certain parachute and opening-process characteristics.

0 5-53

NWC TP 6575

Method 1, W/(CDS)p Method. The equation for the parachute opening force, FX, was

defined in section 5.4.5 as

F. - (CDS)p q Cx X I

where

(CDS)p - the drag area of the full open or reefed parachute, ft2

q - the dynamic pressure at line stretch or disreef, Ib/ft2

C- - the opening-force coefficient at infinite mass, dimensionless (TIbles 5-1

through 5-5). Do not use C. at low canopy loading

X, - the force-reduction factor (the unknown factor in this equation), dimensionless

For an unreefed parachute, the drag area, (CDS)p1 of the full open parachute is used. For

a reefed parachute, a preliminary reefed drag area, (CDS),, can be calculated from the

allowable maximum parachute force, F1, and the dynamic pressure at line stretch:

(CDS)R = F

qC3 Xi

For this preliminary calculation, an opening-force coefflicient, C1, of 1.0 should be used

for the reefed parachute. The force-reduction factor, X1, can be estimated as 1.0 for reefed

drogue chutes and 0.9 for reefed main parachutes.

For the actual force calculations for unreefed parachutes, the force coefficient in

Tables 5-1 through 5-5 applies. Reefed parachutes have different opening-force coefficient

factors for the reefed and disreefed stages. Figures 5-41 and 5-42 show the drag-area-versus�time diagrams for a reefed ringsail and a reefed triconical parachute. There is no drag

overshoot for both parachutes when they open in the reefed stage. Therefore, the opening�force coefficient is 1.0. If evaluations from previous tests are not available, a C, coefficient of

1.1 should be used. For the disreef stage, the force coefficient evaluated from test data should

be used, if available; otherwise, Tables 5-1 through 5-5 will provide acceptable data.

For obtaining the opening-force reduction factor, XI, the canopy loading of the full open

or the individual reefed stages is calculated and the appropriate X1 factor as a function of

canopy loading is found in Figure 5-48.

The amount of parachute force fluctuation in the wake of the forebody must be

considered when calculating the opening force of a small drogue chute behind a large

forebody. This fluctuation is illustrated in Figure 5-49, which shows the effect of the Apollo

space capsule's wake on the opening force of the 16.5-foot-diameter ribbon drogue chute

(Reference 5.10).

5-54

NWC TP 6575

1.0o00

x 0 .8

0

. /

Ur- 0.4 /001

LU

L Dc 0.2 - - F x = (C b) S i) • • • X 1

0

o

U.

0.1

0.0

0.2 0.4 0.6 0.8 1.0 2.0 4.0 6.0 8.0 10 20 40 60 80 100

PARACHUTE CANOPY LOADING, (W/(CD S)p. PSF

FIGURE 5-48. Opening-Force Reduction Factor Versus Canopy Loading.

FORCE-TIME VEHICLE VEH:;LE

TRACE CONFIGUR - DESIGNATION DIAMETER ATION FT

BOILERPLATE 11

SJ COMMAND

MODULE

4(IP CM)

TIME

PARACHUTE $a

TEST VEHICLE

U IPTV )

TIME

INSTRUMENTED 30 CYLINDRICAL

TEST VEHICLE ( ICTV)

ex 1 09

TIME

FIGURE 5-49. Apollo Ribbon Drogue Chute

Force Fluctuation Caused by ForebodyWake

(Inflated Parachute Diameter, Dp. is 10.7 feet)

5-55

NWC TP 6575

The increase in load fluctuation from the small ICTV to the large-diameter boilerplate 0

command module (B/P CM) is apparent in the increase of the force coefficient, C1 , from 1.09 to

1.31. The force coefficient in Figure 5-49 is actually the product C, times X1, called Ck.

However, at the canopy loading of the drogue chute, X1 will be close to 1.0, approaching the

infinite mass condition.

The X1 factor can be obtained from drop tests by calculating

(CDS) q

and then plotting it versus W/(CDS)p. The data in Figure 5-48 were obtained by this method.

The X 1 factor in Figure 5-48 does not include the effect of altitude. Opening forces of

high-canopy-loading parachutes change little with altitude. However, the effect of altitude on

low-canopy-loading parachutes, such as personnel parachutes, is considerable. For

low-canopy-loading parachutes, the X, factors should be used only for altitudes below 15,000

feet. Section 5.5 contains a discussion of the altitude effect on parachute forces.

Ewing evaluated and plotted the Ck = C,,Xt factor from numerous tests of ringsail

parachutes (Reference 5.50).

French recommends plotting a Ck = C,,X 1 factor versus a mass parameter in the form

Do3/m, where Do is the nominal diameter of the parachute and m is the mass of the vehicle and

the parachute assembly (Reference 5.80).

Schilling recommends modifying this mass parameter to the form

Rm = P(CDS)p

3/ 2

mt

where mt is the total mass of vehicle plus decelerator, p is the air density, and (CDS)p is the